Mapping the future of metamaterials

Metamaterials are artificially-structured materials with extraordinary properties not easily found in nature. With engineered three-dimensional (3D) geometries at the micro- and nanoscale, these architected materials achieve unique mechanical and physical properties with capabilities beyond those of conventional materials – and have emerged over the past decade as a promising way to engineering challenges where all other existing materials have lacked success.

Architected materials exhibit unique mechanical and functional properties, but their full potential remains untapped due to challenges in design, fabrication, and characterization. Improvements and scalability in this space could help transform a range of industries, from biomedical implants, sports equipment, automotive and aerospace, and energy and electronics.

“Advances in scalable fabrication, high-throughput testing, and AI-driven design optimization could revolutionize the mechanics and materials science disciplines, enabling smarter, more adaptive materials that redefine engineering and everyday technologies.” says Carlos Portela, the Robert N. Noyce Career Development Professor and assistant professor of mechanical engineering.

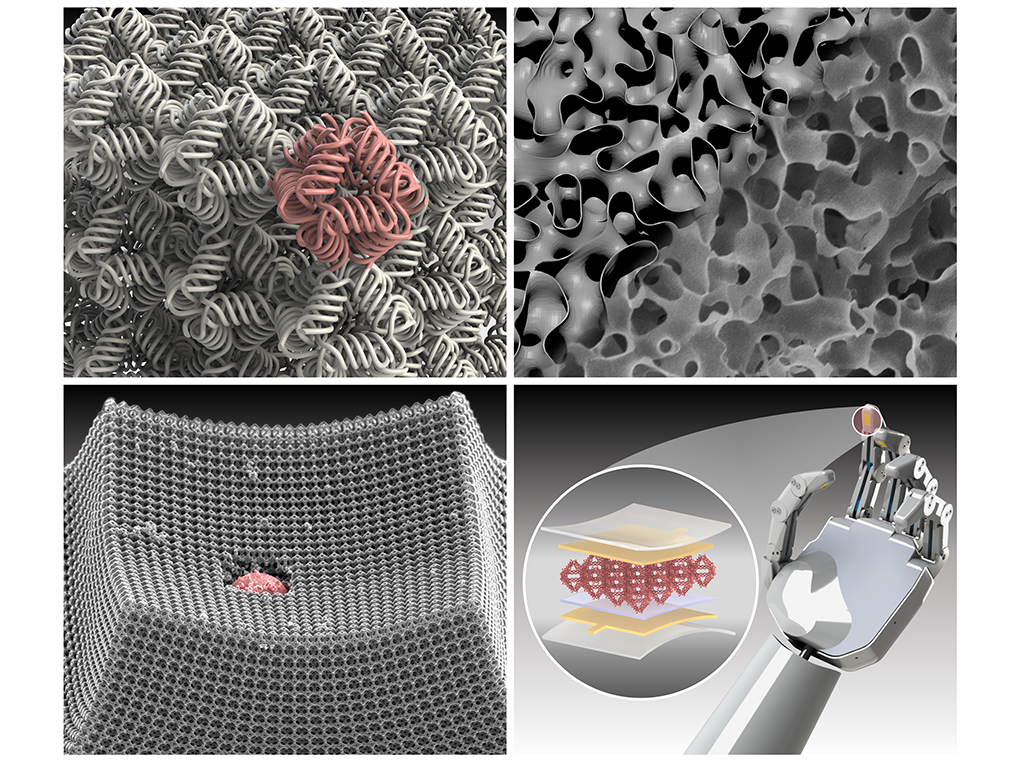

Promising directions in the design, fabrication, characterization, and application of 3D architected materials: 3D woven metamaterials, aperiodic self-assembled morphologies, microscale impact experiments, and pressure sensing functionalities. (Image: Courtesy of the Researchers)

Promising directions in the design, fabrication, characterization, and application of 3D architected materials: 3D woven metamaterials, aperiodic self-assembled morphologies, microscale impact experiments, and pressure sensing functionalities. (Image: Courtesy of the Researchers)In a Perspective published this week by the journal Nature Materials, Portela and James Surjadi, a postdoctoral associate in mechanical engineering, discuss key hurdles, opportunities, and future applications in the field of mechanical metamaterials.

“The future of the field requires innovation in fabricating these materials across length scales, from nano to macro, and progress in understanding them at a variety of time scales, from slow deformation to dynamic impact,” says Portela, adding that it also demands interdisciplinary collaboration.

A Perspective is a peer-reviewed content type that the journal uses to invite reflection or discussion on matters that may be speculative, controversial, or highly-technical, and where the subject matter may not meet the criteria for a Review.

“We felt like our field, following substantial progress over the last decade, is still facing two bottlenecks: issues scaling up, and no knowledge or understanding of properties under dynamic conditions,” says Portela, discussing the decision to write the piece.

Portela and Surjadi’s paper summarizes state-of-the-art approaches and highlights existing knowledge gaps in material design, fabrication, and characterization. It also proposes a roadmap to accelerate the discovery of architected materials with programmable properties via the synergistic combination of high-throughput experimentation and computational efforts, towards leveraging emerging artificial intelligence, machine learning (AI/ML) techniques for their design and optimization.

“High-throughput miniaturized experiments, non-contact characterization, and benchtop extreme-condition methods will generate rich datasets for the implementation of data-driven models, accelerating the optimization and discovery of metamaterials with unique properties,” says Surjadi.

The Portela Lab’s motto is “architected mechanics and materials across scales.” The Perspective aims to bridge the gap between fundamental research and real-world applications of next-generation architected materials, and it presents a vision the lab has been working towards for the last 4 years. The paper, “Enabling three-dimensional architected materials across length scales and timescales,” is available now via Nature Materials.